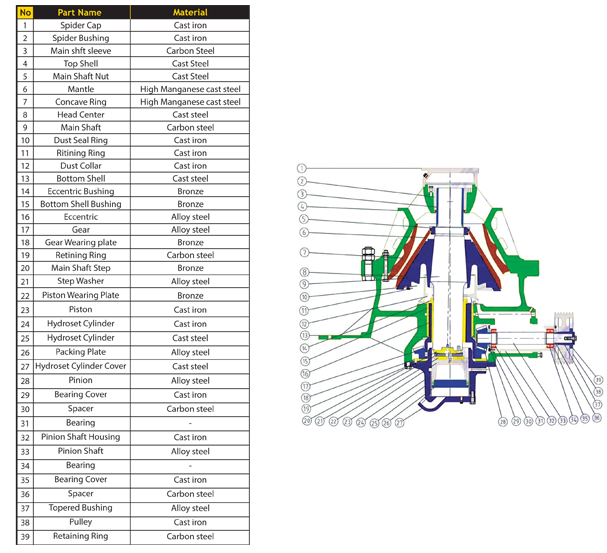

This crusher shaped as a cone type and serves as a secondary crusher. In its crushing operation, hydrocone closes the gap between the mantel and concave by eccentric located at the bottom of the main shaft, driving it to rotate. AS the opening between mantel and concave is shifted by the lifting jack, the load output analysis can be adjusted according to requirements. Furthermore, the eccentric size (cranking rate) can be modified to set the speed and dimension of output load.The main components of the machine in direct contact with the load are entirely made of molybdenum manganese steel with a very high abrasion resistance. This crusher is installed on a chassis along with its hydraulic oil tank and cooling system. The power panel can be switched into fully automatic and manual modes. The panel lets the user control how device functions.