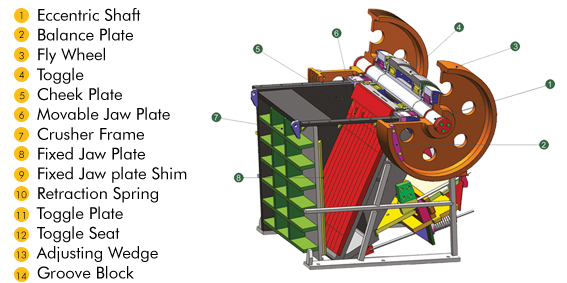

This type of crushers have been designed perfectly for crushing various types of minerals and large rocks in different dimensions. The size of a jaw crusher is determined by the loading inlet at the top of the machine. A jaw crusher reduces the dimensions of rocks entering the device through compression. The shoulder of the jaw falls on a fixed surface (Figure 7).While the moving shoulder blows into the rocks under the force exerted by toggle, the space between the fixed and movable jaws determines the outlet of the jaw, i.e. the maximal size of jaw output. The stones inserted into the machine remain in the crushing chamber until their dimensions are broken down proportional to the lower outlet of the jaw.The output of the crusher is adjustable and the load can move around easily. The precise design of the angle between the fixed and moving shoulders helps the load to easily break down without being thrown upwards.The main body of the crusher is made of steel sheets with large thickness, high strength and suitable elasticity. The points exposed to greater stress and tension are reinforced by heavy lobes made of materials similar to the body itself.